How Sapphires Are Mined: From Rough Stones to Beautiful Gems

Sapphires are one of the most precious and beautiful gemstones in the world. They are loved for their bright colors, especially the deep blue ones, but sapphires can also be found in many other colors, such as pink, yellow, green, and more. The journey of a sapphire stone from being a rough stone buried deep in the earth to a sparkling gem in jewelry is a long and exciting one. In this blog, we will explore how sapphires are mined and transformed into the stunning gems we know and love.

1. Where Are Sapphires Found?

Sapphires are found in several countries around the world. Some of the most famous locations for sapphire mining include:

- Sri Lanka: Known for producing beautiful blue sapphires and the rare pink-orange Padparadscha sapphires.

- Myanmar (Burma): Famous for its deep blue sapphires.

- Australia: Known for producing dark blue to black sapphires.

- Madagascar: One of the largest producers of sapphires in many colors.

- Montana (USA): Produces sapphires in colors like blue, green, and yellow.

Sapphires are formed over millions of years inside the earth, in areas with high heat and pressure. They are often found in ancient riverbeds, where water has eroded the earth and carried the rough stones downstream.

2. How Are Sapphires Mined?

There are two main methods of sapphire mining: traditional mining and mechanical mining. Let’s take a look at both.

a. Traditional Mining

Traditional mining is usually done by hand and is still used in many countries like Sri Lanka and Madagascar. This method is often used in places where sapphire deposits are found in riverbeds.

- Panning: Miners use pans to wash gravel from the riverbeds and separate the heavier sapphire stones from the sand. This method is slow but helps miners find sapphires in a natural, eco-friendly way.

- Digging: In some areas, miners dig small pits or tunnels into the ground to find sapphires. The rough stones are then brought to the surface to be sorted and cleaned.

b. Mechanical Mining

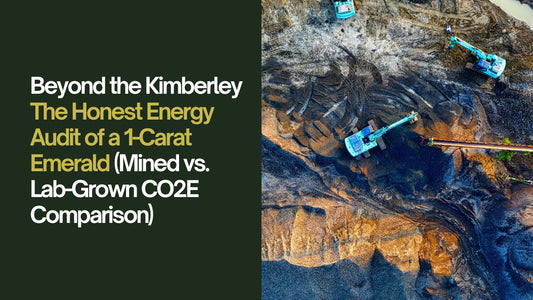

In places where there are large deposits of sapphires, mining machines are used to dig up large amounts of earth and gravel.

- Bulldozers and Excavators: These machines remove the top layers of soil to reach the sapphires hidden below. The gravel is then washed and sorted to find the stones.

- Sluice Boxes: Water is used to wash away the lighter material, leaving the heavier sapphires behind. This method is faster than traditional panning but requires more equipment.

3. Sorting and Grading the Sapphires

Once the rough sapphires are mined, they must be sorted and graded before being sent to gem cutters.

- Rough Sorting: The first step is to sort the sapphires by size and color. Not all sapphires are gem-quality, so miners separate the high-quality stones from the lower-quality ones.

- Grading: After sorting, the sapphires are graded based on their color, clarity, and size. Only the best stones will be chosen to be cut and polished.

Example: In Sri Lanka, skilled gem sorters carefully inspect each sapphire by hand, looking for stones with deep color and few inclusions.

4. Cutting and Polishing the Sapphires

Cutting and polishing sapphires is a delicate process that requires skill and precision. The goal is to bring out the sapphire’s natural beauty and make it sparkle.

- Cutting: The rough sapphire is first cut into a shape, such as a round, oval, or cushion cut. The cutter must carefully choose the best angles to maximize the gem’s brilliance and color.

- Faceting: After the sapphire is cut, small facets (flat surfaces) are added to the stone. These facets help reflect light and make the sapphire shine.

- Polishing: Finally, the sapphire is polished to give it a smooth, shiny surface. A well-polished sapphire will have a bright, reflective surface that shows off its color and sparkle.

Example: Blue sapphires often look best in round or oval cuts, while pink or yellow sapphires can be cut in more unique shapes like pear or heart.

5. Treatments to Enhance Sapphires

Some sapphires are treated to enhance their color and clarity. These treatments are commonly used to improve the appearance of lower-quality sapphires.

- Heat Treatment: This is the most common treatment used to improve the color of sapphires. The stones are heated at high temperatures to remove any brown or gray tones and make the color more vibrant.

- Surface Diffusion: This treatment adds a thin layer of color to the surface of the sapphire, usually to enhance its blue color. However, this treatment is less permanent and may fade over time.

6. Final Step: Setting the Sapphire in Jewelry

Once the sapphire has been cut, polished, and treated, it is ready to be set in jewelry. Sapphires are used in all types of gemstone jewelry, including rings, necklaces, earrings, and bracelets. The deep blue of a sapphire is especially popular in engagement rings, but other colors like pink, yellow, and green are also becoming more popular.

Example: The famous blue sapphire engagement ring worn by Princess Diana and now by Kate Middleton is one of the most famous sapphire rings in the world. It features a large oval blue sapphire surrounded by diamonds.

Conclusion

The journey of a sapphire from a rough stone in the earth to a beautiful, sparkling gem in a piece of jewelry is long and fascinating. Whether they are mined by hand in riverbeds or using machines in large-scale operations, sapphires must go through a careful process of sorting, cutting, and polishing to bring out their true beauty. With their rich history, stunning colors, and royal connections, sapphires will continue to be one of the most treasured gemstones in the world